Case Study: car seat strenght assessment

More simulation at the start means less rework later on.

More simulation at the start means less rework later on.

Savage Rivale teamed up with Femto Engineering to assess their car seat concept design. Of course Savage Rivale could have moved on to physical testing right away, but they chose to incorporate advanced simulation to virtually test and optimize their design first. In this case study we give you an exclusive look behind the scenes of this process.

Savage Rivale teamed up with Femto Engineering to assess their car seat concept design. Of course Savage Rivale could have moved on to physical testing right away, but they chose to incorporate advanced simulation to virtually test and optimize their design first. In this case study we give you an exclusive look behind the scenes of this process.

Savage Rivale is a design studio with a focus on automotive design and engineering. They are specialized in beyond exotic and niche car concepts such as their 4 door convertible sports car called the Roadyacht GTS and the 4 person beach cruiser named the Coastrunner. Savage Rivale has Dutch roots, but chances are bigger you see their cars on the roads around the Mediterranean.

Savage Rivale’s core strength is to combine old school craftsmanship (all cars are built by hand) with state of the art CAD modeling. To get the best results on validation they chose FEMTO for guaranteeing the legal and safety side of the products such as chassis strength, safety belt design etc.

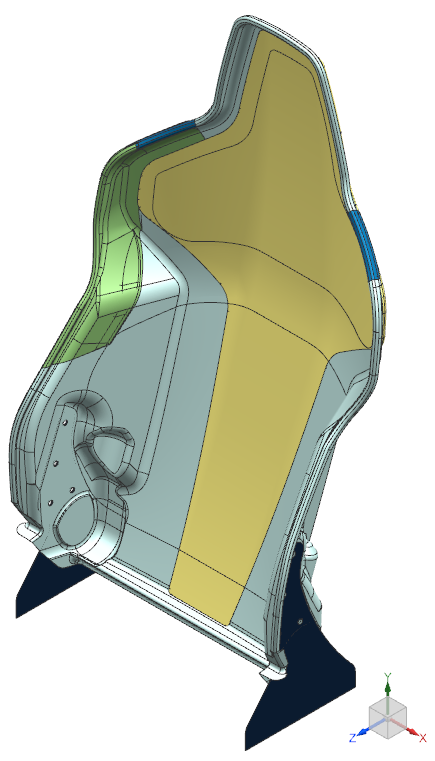

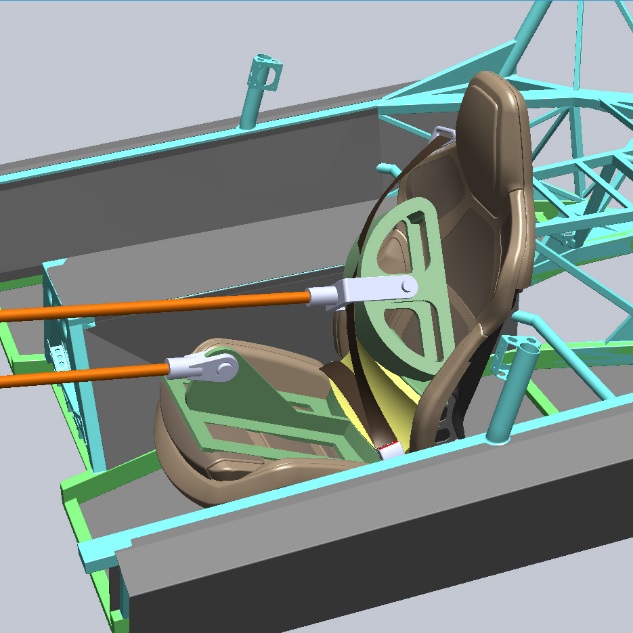

In this case Savage Rivale wants to verify the strength of the  prototype model of their car seat. In this case we subjected the seat to a load applied on the seat belt attachment area. The challenge that Savage Rivale faces is to make the seat as lightweight as possible without compromising on structural integrity. In order to accomplish this, they choose to incorporate a variety of materials. The seat is mainly fabricated from a pre-preg laminate. The back of the seat (yellow) is reinforced with structural foam and the area close to the seat belt attachment (green) is reinforced with an aluminum insert. These different layers make strength assessment not straightforward, but handling complicated compositions like this, is just why clients call us.

prototype model of their car seat. In this case we subjected the seat to a load applied on the seat belt attachment area. The challenge that Savage Rivale faces is to make the seat as lightweight as possible without compromising on structural integrity. In order to accomplish this, they choose to incorporate a variety of materials. The seat is mainly fabricated from a pre-preg laminate. The back of the seat (yellow) is reinforced with structural foam and the area close to the seat belt attachment (green) is reinforced with an aluminum insert. These different layers make strength assessment not straightforward, but handling complicated compositions like this, is just why clients call us.

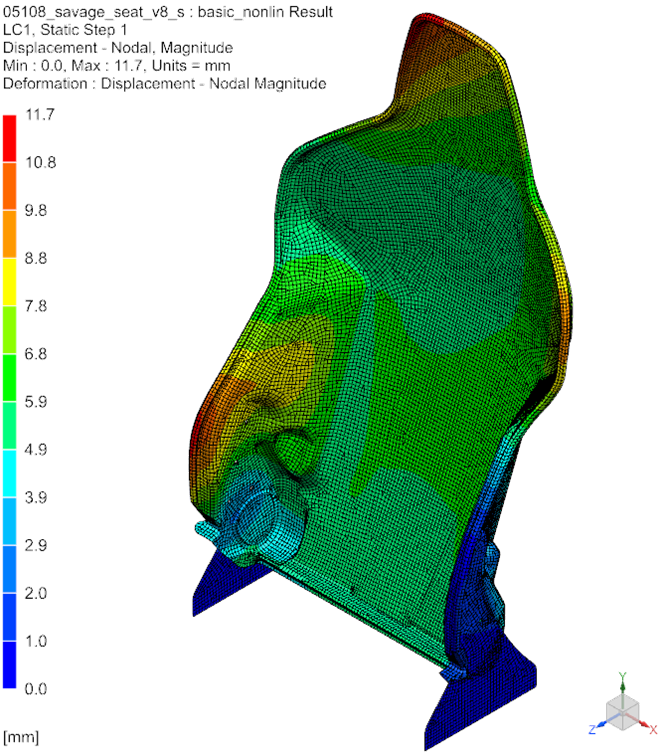

Our engineers considered yield failure of the different materials, stresses and safety factors to simulate the different layers and materials in the car seat accurately. Initial results showed some critical locations in the seat that required further assessment. Overall we concluded that the pre-preg laminate could withstand the simulation tests we performed on it. We also recommended some of the critical locations to be reinforced with another material. Our engineers took into consideration that the seat had to be lightweight and suggested the use of a specific type of aluminum reinforcements.

Our engineers considered yield failure of the different materials, stresses and safety factors to simulate the different layers and materials in the car seat accurately. Initial results showed some critical locations in the seat that required further assessment. Overall we concluded that the pre-preg laminate could withstand the simulation tests we performed on it. We also recommended some of the critical locations to be reinforced with another material. Our engineers took into consideration that the seat had to be lightweight and suggested the use of a specific type of aluminum reinforcements.

This type of Finite Element Model (FEM) strength  and stress assessment meant the car seat design was virtually tested before moving on the actual physical testing. This in turn, led to more confidence in the design and less last minute engineering rework for the Savage Rivale team.

and stress assessment meant the car seat design was virtually tested before moving on the actual physical testing. This in turn, led to more confidence in the design and less last minute engineering rework for the Savage Rivale team.

This type of FE strength and tress assessment meant Savage Rivale did not have to undergo a series of prototype testing in order to find a suitable design, which save them time and money. They went into the prototyping phase with more confidence knowing that their design was strong enough.

“At Femto Engineering, quality and efficiency go hand-in-hand”.

It is very easy to be impressed with the pretty colors of FEM results, but for them to match real-world conditions you should know the science behind them. At Femto Engineering we believe a tool is only as good as the hands that wield it. But we also believe that great tools are able to leverage knowledge, experience and skills at a scale no human could. From our software portfolio we chose Siemens Simcenter 3D to get the Savage Rivale project through the door. As Simcenter 3D is just one of tools at our disposal, we’re in the privileged position to have so many options to choose from. Exceptional geometry associativity in the software means simulation models are automatically updated when geometry is created, edited or repaired. Design flaws are easily visualized and design iterations are quickly executed. Simcenter 3D and NX form a coherent CAD/CAE environment, narrowing the gap between design and advanced analyses, giving designers and analysts more options to work with. We are a Simcenter 3D buyer, reseller and end user and are available to give sound advice on what to look out for in selecting the right tool for your engineering setup.

We hope you liked this case study. Want to read more content like this? Follow us on LinkedIn, Twitter or Facebook Also if you are interested in our consultancy and software solutions get in touch!

Do you need more information or want to discuss your project? Reach out to us anytime and we’ll happily answer your questions.

At Femto Engineering we help companies achieve their innovation ambitions with engineering consultancy, software, and R&D.

We are Siemens DISW Expert Partner for Simcenter Femap, Simcenter 3D, Simcenter Amesim, Simcenter STAR-CCM+ and SDC verifier. Get in touch and let us make CAE work for you.

Sign up for our newsletter to get free resources, news and updates monthly in your inbox. Share in our expertise!